Battery pack / module test solution

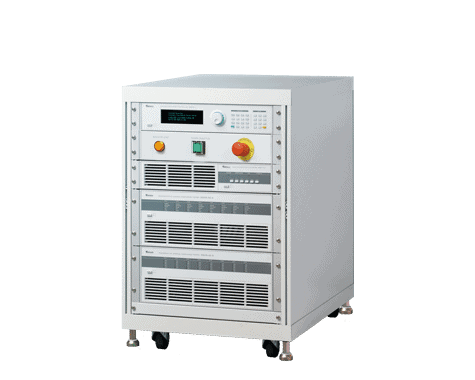

The Chroma 17040 Regenerative Battery Pack Test System is a high precision system specifically designed for secondary battery module and pack tests. It has an energy regenerative function to greatly reduce power consumption during discharge, and ensure a stable power grid without generating harmonic pollution on other devices even in dynamic charge and discharge conditions. It is capable of recycling the electric energy discharged by the battery module back to the grid reducing wasted energy that is discharged by traditional equipment in the form of heat, thus reducing the HVAC requirements.

■ Conforms to international standards for battery testing: IEC, ISO, UL, and GB/T, etc.

■ Regenerative battery energy discharge (Eff. >90%, PF >0.95, I_THD

■ Multiple voltage and current ranges for auto ranging function to provide optimum resolution

■ High accuracy current/voltage measurement (±0.05%FS/±0.02%FS)

■ 2ms current slew rate (10%~90%)

■ Dynamic (current/power) driving profile simulation tests for NEDC, FUDS, HPPC

■ Automatic protection for error condition

■ Battery simulator (option)

■ High power testing equipment – Voltage range : 60~1000V – Current range : 0~750A – Power range : 0~300kW

■ Customized integration functions – Integrated temperature chamber – BMS data analysis – Multi-channel voltage/temperature recording

Chroma's 17020 is a high precision system specifically designed for secondary battery module and pack tests. Highly accurate sources and measurements ensure that the test quality is suitable for performing repetitive and reliable tests crucial for battery modules/packs, incoming, and outgoing inspections as well as capacity, performance, production, and qualification testing.

■ Regenerative battery energy discharge, efficiency 85% – Energy saving – Environment protection – Low heat generate

■ Channels paralleled for higher currents

■ Charge/discharge modes (CC, CV, CP) – Power Range: 600W, 1.25KW, 2.5KW, 5KW, 10KW, 20kW, 30kW, 50kW, 60KW per channel – Voltage Range: 20V, 60V, 100V, 200V, 500V per channel – Current Range: up to 2600A (parallel)

■ Driving cycle simulation

■ High precision measurement

■ Fast current conversion

■ Smooth current without overshoot

■ Test data analysis function

■ Data recovery protection (after power failure)

■ Independent protection of multi-channel

■ BMS data recording

■ Thermal chamber control integration

■ Test channel parallel function

■ Test data analysis function

■ Data recovery protection

Chroma 87001 Battery Cell Simulator is a high precision, programmable, and bidirectional DC power source with both voltage source and current source functions. In addition, the model can be used as a multi-channel DC power supply or an electronic load as well. A single simulator has 16 channels and each of them can set voltage and current respectively via Chroma software. The Chroma 87001 Battery Cell Simulator can be used in place of lithium-ion batteries to provide a reliable and safe testing e n v iron m e n t. T h e equipped battery management system (BMS) and its subsystems can test the battery cells used in electric vehicles and energy storage batteries, etc. The simulator has voltage isolated channels that can simulate a 480-cell battery pack (2000V/4.2V) connected in series

Operating mode : CC/CP – Channel power 25W – Channel voltage 5V – Channel current 5A (parallelable)

■ Bidirectional power supply design

■ Serial and parallel connection function

■ 480-cell battery pack voltage simulation ability (connected in series)

■ High precision current and voltage measurement

■ 2 current ranges for selection per channel

■ Current sharing design for parallel operation mode

■ Fast voltage setting for rise/fall speed : time (1ms)

■ Switch fast charge and discharge current in current source mode without any interruption ■ Low output noise

■ Independent channel over-voltage, current limit, and over-temperature protection

■ Standard Ethernet control interface

■ CE certification granted